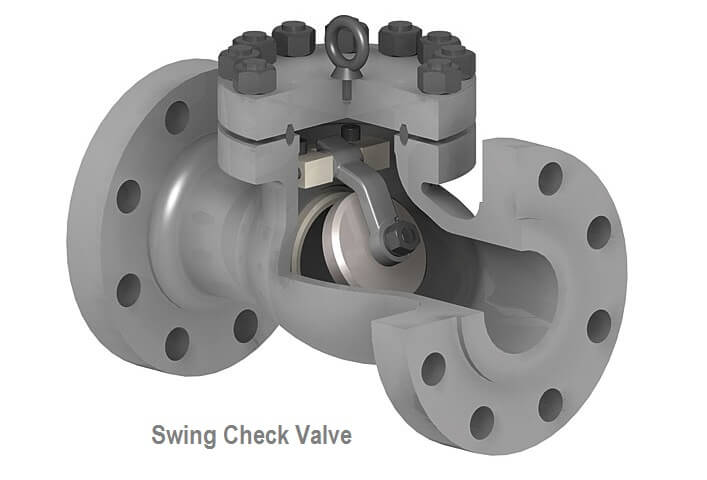

Swing Check Valves Manufacturers

Bolted Bonnet Cast Carbon, Stainless or Alloy Steel

Size: 2" -24", ASME Class: 150# -600#

Design Features

- Trims:- 13% Cr Hinge Pine, 13 Crfaced Disc and CoCr alloy faced Seat APITrip S Suitable for Applications up to S50° F (454° C).

- Body and Cover casting are precision Machined.

- Disc Assembly:- Non-rotating disc is fastened securely to disc hanger with a lock nut and cotter pin. Disc hanger is supported on a sturdy disc carrier hinge pin of excellent bearing qualities. All parts accessible from the top for easy servicing.

- Flanges :Finish 125-250 AARH for all Valves. ASME Classes 150-300 :2 mm raised face ASME Classes 600-up : 7 mm Raised faced

- Disc:- One-piece Construction to withstand the severe shock of check valve service. Hard-faced with 13% Cr., CoCr alloy, SS 316 or Monel,Ground and lapped with seat.

- RTJ available on client requirement.

- RTJ available on client requirement.

- Body and Bonnet Joint accurately Machined. Spiral Wound with Different Grade of Material.

Standard Materials

| Parts | Materials | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Cover | WCB | CF8 | CF8M |

| Hinge Pin | SS 410 | SS 304 | SS 316 |

| Disc | CA 15 or 13Cr faced WVB | CF8 | CF8M |

| Seat | 13% Cr. or Steel | CoCr Alloy Faced | CoCr Alloy Faced |

| Gasket | Class 150: Corrugated Steel / Graphite Class 300 - 1500: Spiral Stainless Steel / Graphite |

||

| Boby/Cover Nut | Gr.2H | Gr.8 | Gr.8M |

| Body/Cover Stud | Gr.B7 | Gr.B8 | B8M |

| Name Plate | Stainless Steel | ||

Design Specifications

| Item | Applicable STD. | ||

|---|---|---|---|

| Wall thickness and general design ≤ NPS 24 | API 600, ISO 1868 | ||

| Wall thickness and general design > NPS 24 | ASME B16.34 | ||

| Pressure Temperature Rating | ASME B16.34 | ||

| Face-to-Face dimensios for butt weld and flanged valves | ASME B16.10 | ||

| Testing Standard | API 598 | ||

| Flange Design | ASME B16.5 | ||

| Butt Welding Design | ASME B16.25 | ||

| Materials | ASTM | ||

Swing Check Valve Dimensions

| Dimensional Details As Per ANSI 150 # Class | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 2" | 2 1/2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

| F to F | 203 | 216 | 241 | 292 | 356 | 495 | 622 | 699 | 787 | 914 | 978 | 978 | 1295 |

| OD | 150 | 180 | 190 | 230 | 280 | 345 | 405 | 485 | 535 | 595 | 635 | 700 | 815 |

| THK | 17.5 | 20.7 | 22.3 | 22.3 | 25.4 | 28.6 | 30.2 | 31.8 | 33.4 | 35 | 38.1 | 41.3 | 46.1 |

| RFD | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| PCD | 120.7 | 139.7 | 152.4 | 190.5 | 241.3 | 298.5 | 362 | 431.8 | 476.3 | 539.8 | 577.9 | 635 | 749.3 |

| od | 19.05 | 19.05 | 19.05 | 19.05 | 22.23 | 22.23 | 25.4 | 25.4 | 28.58 | 28.58 | 31.75 | 31.75 | 34.93 |

| NOH | 4 | 4 | 4 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 |

| Dimensional Details As Per ANSI 300 # Class | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 2" | 2 1/2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

| F to F | 266.7 | 292.1 | 317.5 | 355.6 | 444.5 | 533.4 | 622.3 | 711.2 | 838.2 | 863.6 | 977.9 | 1016 | 1346.2 |

| OD | 165 | 190 | 210 | 255 | 320 | 380 | 445 | 520 | 585 | 650 | 710 | 775 | 915 |

| THK | 20.7 | 23.9 | 27 | 30.2 | 35 | 39.7 | 46.1 | 49.3 | 52.4 | 55.6 | 58.8 | 62 | 68.3 |

| RFD | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| PCD | 127 | 149.2 | 168.3 | 200 | 269.9 | 330.2 | 387.4 | 450.8 | 514.4 | 571.5 | 628.6 | 685.8 | 812.8 |

| od | 19.05 | 22.22 | 22.22 | 22.22 | 22.22 | 25.4 | 28.57 | 31.75 | 31.75 | 34.93 | 34.93 | 34.93 | 41.28 |

| NOH | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 16 | 20 | 20 | 24 | 24 | 24 |