Butterfly Valves Manufacturer in India

Welcome to Metflow Engineers, serving the industry as top-notch Butterfly Valves Manufacturer In India while remaining committed to the innovation and excellence that pushes us forward. We offer exceptional products that cater to your needs by using advanced manufacturing techniques and having the stringent quality control system in place. Our butterfly valves are durable and reliable thereby serving as a solution that brings value over a period of time.

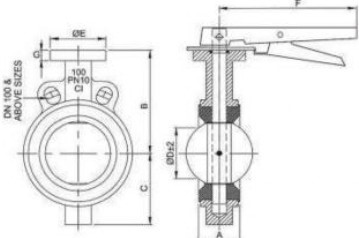

High Performance Cast Carbon, Stainless or Alloy Steel Size: 1 1/2" -28", ASME Class: PN10 -PN25

Design Features

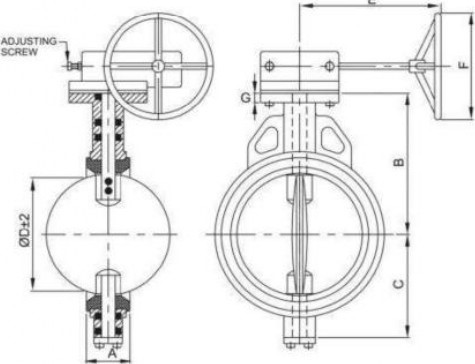

- Slim Seal, Wafer Type,Double Flanged Type Double Eccentric, Triple Eccentric.

- 100% tight shut off in both f low directions.

- REPLACEABLE/ Molded rubber seat in various material.

- A fully universal body design ensures suitable for mounting between all popular standards (VIZ: - ANSI,BS,DIN,IS, JIS, etc.)

- The notch disc & band lever ensures locking of the valves in S intermediate positions in addition to close and open position.

- Face to face water short dimensions conform to BS 5155 I API 609 I IS 13095 I AWWA C 504.

- Lever Operated,Gear Operated, Pneumatic and Electrical Actuator operated.

Standard Materials

| Parts | Materials | |||

|---|---|---|---|---|

| Body & Side Piece | CI | WCB | CF8 | CF8M |

| Disc | CI / WCB / CF8 / CF8M | WCB / CF8 / CF8M | CF8 / CF8M | CF8M |

| Stem | SS 410 / 17-4 PH / SS 304 / SS 316 | SS 410 / 17-4 PH / SS 304 / SS 316 | SS 304 | SS 316 |

| Lining | EPDM / NITRILE / VITON / PTFE / PFA | |||

| Stem Packing | NBR / VITON / PTFE | |||

| Lever | IC CASTED, IN ALL MOC | |||

| Stud - Nut | GR. B7 / 2H | GR. B7 / 2H | GR. 8 | GR. 8M |

| Anme Plate | Stainless Steel / Alluminium | |||

Design Specifications

| Item | Applicable STD | ||

|---|---|---|---|

| Design Standard | API 6D / BS 5351 | ||

| Fire Safe Standard | API 607 / API 6FA | ||

| Pressure Temperature Rating | ASME B16.34 | ||

| Face-to-Face Dimensios | ASME B16.10 | ||

| Testing Standard | API 598 / BS 6755 | ||

| Flange Design | ASME B16.5 | ||

| Materials | ASTM | ||

- Efficient flow control especially for applications that need quick adjustments.

- Space-saving design, particularly important in installation where there is a limited space.

- Cost-effectiveness while still maintaining efficient operation and durability.

- Ability to withstand harsh operating conditions such as temperature fluctuations, corrosive environments and high pressure.

- Versatile enough to suit different fluids such as gases, slurries and liquids.

- Ease of installation and maintenance with the best butterfly valve supplier in India by your side.

Why Quality Matters in Butterfly Valves

Metflow Engineers’ high-quality butterfly valves meet these industry standards and quality expectations. The compliance is also maintained well to ensure safety of your industrial processes. Notably, choosing the right butterfly valves is not only about the performance but also about ensuring the safety and reliability of your entire system.

Why Choose Metflow Engineers as Your Butterfly Valves Manufacturer In India

As a leading butterfly valve supplier in India, Metflow Engineers understands that you have your unique needs. Hence, we have turned up with the valves having features that address your concerns well. We use quality materials such as stainless, cast carbon and alloy steel to manufacture valves. Our butterfly valves are available in sizes that may range from 1 1/2" to 28" and also accommodate ASME classes PN10 to PN25. Thus, they can be integrated in different systems easily. Furthermore, our valves offer 100% tight shut-off in both flow directions. This could prevent leaks efficiently. There are customization options. Metflow Engineers provides replaceable molded rubber seats in different materials thereby meeting your application needs. The valves are compatible with standards which are widely accepted such as BS, DIN, ANSI, JIS, and IS. For gear-operated, lever-operated, electrical actuator-operated and pneumatic designs, they serve as flexible solution.

- Compliance to design standards API 6D and BS 5351 standards

- Compliance with API 607 and API 6FA fire safe standards

- ASME B16.34 specification for pressure and temperature rating

- ASME B16.10 standards for face-to-face dimensions

Fulfilling the Parameters:

Achieve Operational Excellence with Metflow Engineers Quality Valves!

Quality, to Metflow Engineers is our ethos. Being an ISO 9001-2015 certified company, our manufacturing processes follow stringent quality standards. Every valve we produce undergoes rigorous inspection by our team of qualified engineers. Enhance your operations with our top-notch butterfly valves. We are here to help contact us now!

Gear Operated Butterfly Valve : PN 10 / PN 16

| DN | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| 50 | 43 | 104 | 61 | 28 | 65 | 185 | 15 |

| 65 | 46 | 111 | 68 | 48 | 65 | 185 | 15 |

| 80 | 46 | 124 | 75 | 67 | 65 | 230 | 15 |

| 100 | 52 | 140 | 89 | 88 | 65 | 230 | 15 |

| 125 | 56 | 158 | 105 | 114 | 65 | 230 | 15 |

| 150 | 56 | 180 | 120 | 142 | 65 | 265 | 15 |

| 200 | 60 | 230 | 156 | 194 | 75 | 325 | 15 |

| 250 | 68 | 566 | 196 | 243 | 75 | 385 | 18 |

| 300 | 78 | 300 | 230 | 292 | 75 | 385 | 18 |

Gear Operated Butterfly Valve : PN 10 / PN 16

| DN | A | B | C | D | E | F | G | FLANGE STD. ISO 5211 |

|---|---|---|---|---|---|---|---|---|

| 100 | 52 | 157 | 100 | 88 | 180 | 200 | 15 | F07 |

| 125 | 56 | 164 | 115 | 114 | 180 | 200 | 15 | F07 |

| 150 | 56 | 181 | 133 | 142 | 240 | 250 | 15 | F07 |

| 200 | 60 | 230 | 165 | 194 | 285 | 350 | 15 | F10 |

| 250 | 68 | 266 | 196 | 243 | 285 | 350 | 18 | F10 |

| 300 | 78 | 300 | 230 | 292 | 285 | 350 | 18 | F10 |

| 350 | 92 | 320 | 272 | 330 | 300 | 350 | 22 | F12 |

| 400 | 102 | 385 | 302 | 375 | 305 | 350 | 22 | F14 |

| 450 | 114 | 405 | 325 | 425 | 305 | 450 | 25 | F14 |

| 500 | 127 | 465 | 405 | 470 | 350 | 500 | 26 | F16 |

| 600 | 154 | 540 | 460 | 570 | 370 | 600 | 26 | F16 |