Globe Valve Manufacturer in India

Bolted Bonnet Cast Carbon, Stainless or Alloy Steel

Size: 2" -24", ASME Class: 150# -600#

Design Features

- Trims:- 13% Cr Stem, 13 Cr faced Plug and CoCr alloy faced Seat APITrip 8 Suitable for Applications up to 850° F (454° C).

- Body and Bonnet casting are precision Machined. one-piece bonnet for better alignment and fewer parts.

- Tapered Disc accurately mates the hard-faced surface of the disc with the surface of the seat,Hard-faced with 13% Cr., CoCr alloy,SS 316 or Monel, Ground and lapped with seat.

- Flanges :Finish 125-250 AARH for all Valves. ASME Classes 150-300 :2 mm raised face ASME Classes 600-up : 7 mm Raised faced

- Non-Rotating stem with precision acme Threads and Burnished finish. Double Acme For Faster Operation.

- RTJ available on client requirement.

- Body and Bonnet Joint accurately Machined. Spiral Wound with Different Grade of Material.

- Rotating stem nut is austenitic Ductile iron Gr.D-2C renewable in line.

Advantages of Using Globe Valve for Different Industrial Purposes

Globe valve are linear motion valves that are used to start, stop, and throttle the flow. They are designed with the help of a stem that moves up and down to regulate the flow inside the valve. The globe valve supplier has designed it in a way that helps in the regulation of the flow using the movable disk and the special seat. The globe valve are named after their spherical shape with two halves of the body which are separated by an internal baffle.

How Do Globe Valve Work?

The globe valve can restrict and permit the flow of a medium. When the valve is opened and the disk is moved away from the seat, the fluid is allowed to pass through the valve. On the contrary, when the globe valve is sealed, the disk comes in contact with the seat. This ensures the flow of the fluid is at a halt. This mechanism makes the globe valve reliable and efficient in controlling the fluid flow.

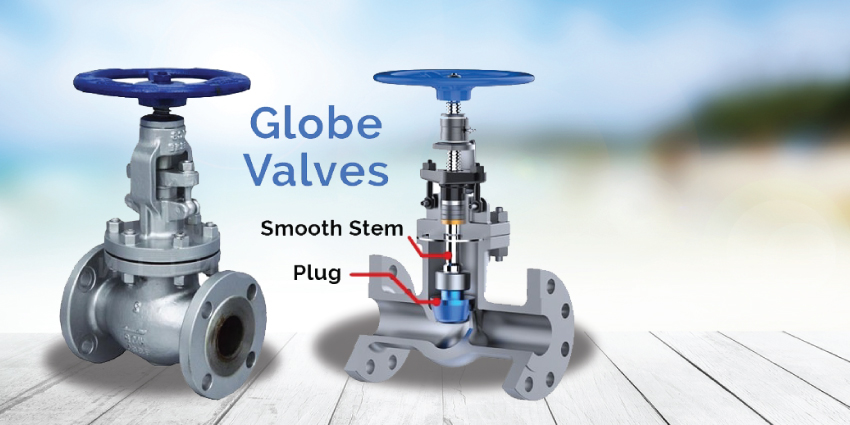

Key Components of Globe Valve

Body : This is the main structure which is spherical and has all the internal components in it.

Disk : This component is moved to open or close the valve.

Seat : The stationary ring that forms a seal with the disk is the seat. It helps in stopping the fluid flow when the valve is closed.

Stem : It connects the disk to the actuator and transmits the motion to open or close the valve.

Bonnet : The component that is used to cover the opening in the body is the bonnet.

Advantages of of Globe Valve

Here are the advantages explained by the leading globe valve supplier:

Controlled precision:

This unique feature helps the globe valve become capable of controlling the flow of the liquid. It demonstrates a relationship between the seat and the disc which allows for fine adjustments to the flow rate. Controlled precision is essential in places where exact control of pressure, flow, and temperature is needed. This ensures efficiency and safety and makes it a valuable asset for managing fluid dynamics.

It prevents leakage:

The valves are designed to provide a tight seal when closed. It minimizes the risk of leakages and the seat and the disc configuration ensures the closed position of the valve. The enhancing sealing properties of the globe valve contribute to safer operational environments and reduced material loss.

Versatile applications:

They have a wide range of applications and can be used for different fluids including steam, gas, oil, water, and other substances. The globe valve can be operated effectively under high pressure and temperature. This makes it suitable for diverse industrial applications including chemical industries and power generation industries as well.

Ease of maintenance:

Globe valve are durable, reliable, and safe to use. It is designed in a way to allow for easy access to internal components such as discs, seats, and other components. The valve enables quick replacements and adjustments without the need for complete valve removal from the pipeline. The low maintenance requirements help in reduced operational costs, and downtime and ensure a more reliable and smooth system performance.

Choose Metflow Engineers for Premium Quality Products

Metflow Engineers is the leading Globe Valve Manufacturer in India that offers the best quality globe valve to its clients. Our products are used in different industrial applications including the chemical sector, oil sector, pharma industries, pulp sector, and many more sectors.

Metflow Engineers is a renowned Globe Valve Manufacturer in India, offering premium-quality globe valves designed for precise flow control and long-lasting performance. Our valves are built to withstand challenging industrial conditions, making them ideal for sectors such as oil and gas, chemical processing, and power generation. As a reliable Globe Valve Supplier, we provide a comprehensive range of globe valves in various sizes and materials to meet the specific requirements of our clients. With a focus on innovation and customer satisfaction, Metflow Engineers is committed to delivering exceptional valve solutions tailored to your needs.

Get in touch with the best Globe Valve Manufacturer in India.

Standard Materials

| Parts | Materials | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Bonnet | WCB | CF8 | CF8M |

| Stem | SS 410 | SS 304 | SS 316 |

| Plug | CA 15 or 13Cr faced | CF8 | CF8M |

| Seat | 13% Cr. or Steel | CoCr Alloy Faced | CoCr Alloy Faced |

| Packing Flanged | Carbon Steel | Stainless steel | Stainless Steel |

| Gland Bushing | Carbon Steel | Stainless steel | Stainless steel |

| Packing ring | Graphite | ||

| Gland Stud | Gr. B7 | Gr. B8 | B8M |

| Gland Nut | Gr.2H | Gr.8 | Gr.8M |

| Boby/Bonnet Nut | Gr.2H | Gr.8 | Gr.8M |

| Body/Bonnet Stud | Gr.B7 | Gr.B8 | B8M |

| Back Seat | SS 410 | SS 304 | SS 316 |

| Gasket | Class 150: Corrugated Steel / Graphite Class 300 - 1500: Spiral Stainless Steel / Graphite |

||

| Hinge Pin | AISI 410 | SS 304 | SS 316 |

| Yoke Bushing | Carbon Steel | Stainless Steel | Stainess Steel |

| Stem Nut | A 439 Austenitic Ductile Iron Gr.D-2c | ||

| Handwheel Nut | Malleable Iron or Steel | ||

| Handwheel | Malleable Iron or Ductile Iron | ||

Design Specifications

| Item | Applicable STD. | ||

|---|---|---|---|

| Wall thickness and general design ≤ NPS 24 | API 600, ISO 1873 | ||

| Wall thickness and general design > NPS 24 | ASME B16.34 | ||

| Pressure Temperature Rating | ASME B16.34 | ||

| Face-to-Face dimensios for butt weld and flanged valves | ASME B16.10 | ||

| Testing Standard | API 598 | ||

| Flange Design | ASME B16.5 | ||

| Butt Welding Design | ASME B16.25 | ||

| Materials | ASTM | ||

Globe Valve Dimensions

| Dimensional Details As Per ANSI 150 # Class | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 2" | 2 1/2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

| F to F | 203 | 216 | 241 | 292 | 406 | 495 | 622 | 699 | 787 | 914 | 978 | 978 | 1295 |

| OD | 150 | 180 | 190 | 230 | 280 | 345 | 405 | 485 | 535 | 595 | 635 | 700 | 815 |

| THK | 17.5 | 20.7 | 22.3 | 22.3 | 25.4 | 28.6 | 30.2 | 31.8 | 33.4 | 35 | 38.1 | 41.3 | 46.1 |

| RFD | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| PCD | 120.7 | 139.7 | 152.4 | 190.5 | 241.3 | 298.5 | 362 | 431.8 | 476.3 | 539.8 | 577.9 | 635 | 749.3 |

| od | 19.05 | 19.05 | 19.05 | 19.05 | 22.23 | 22.23 | 25.4 | 25.4 | 28.58 | 28.58 | 31.75 | 31.75 | 34.93 |

| NOH | 4 | 4 | 4 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 |

| Dimensional Details As Per ANSI 300 # Class | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 2" | 2 1/2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

| F to F | 266.7 | 292.1 | 317.5 | 355.6 | 444.5 | 558.9 | 622.3 | 711.2 | - | - | - | - | - |

| OD | 165 | 190 | 210 | 255 | 320 | 380 | 445 | 520 | 585 | 650 | 710 | 775 | 915 |

| THK | 20.7 | 23.9 | 27 | 30.2 | 35 | 39.7 | 46.1 | 49.3 | 52.4 | 55.6 | 58.8 | 62 | 68.3 |

| RFD | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| PCD | 127 | 149.2 | 168.3 | 200 | 269.9 | 330.2 | 387.4 | 450.8 | 514.4 | 571.5 | 628.6 | 685.8 | 812.8 |

| od | 19.05 | 22.22 | 22.22 | 22.22 | 22.22 | 25.4 | 28.57 | 31.75 | 31.75 | 34.93 | 34.93 | 34.93 | 41.28 |